2025 How to Build an Effective Filter System for Your Needs

In today's increasingly complex environment, the importance of a tailored filter system cannot be overstated. A robust filtration setup not only enhances the quality of water and air but also significantly impacts health and overall well-being. According to a report by the World Health Organization, approximately 2 billion people worldwide lack access to safely managed drinking water, underscoring the critical need for effective filtration solutions. The right filter system can mitigate contaminants that pose health risks, making informed choices essential for consumers and industries alike.

Moreover, advancements in filter technology are revolutionizing how we approach filtration needs. The global water and wastewater treatment market is projected to reach USD 610 billion by 2025, reflecting an increasing demand for efficient filter systems in various applications. As modern challenges continue to evolve, understanding how to build an effective filter system tailored to specific requirements becomes a pivotal consideration for both residential and industrial users. This article aims to guide you through the essential components and strategies necessary to create a filter system that meets your unique needs, ensuring optimal performance and safety.

How to Define Your Specific Filtering Needs for 2025

In 2025, defining your specific filtering needs is crucial for building an effective filter system. According to a recent report by MarketsandMarkets, the global demand for filtration solutions is expected to reach USD 70 billion by 2025, driven by industries such as water treatment, air purification, and industrial processes. To tailor a filter system that meets these demands, organizations must first assess their unique requirements, including the types of contaminants they need to address and the specific applications they are targeting.

Understanding the filtration needs involves a thorough analysis of operational parameters, such as flow rate, particle size, and environmental conditions. For instance, a study published by the American Filtration and Separations Society highlights that nearly 30% of companies experienced performance issues due to inadequate filtering systems. By prioritizing the identification of key contaminants, such as microbes in water or particulate matter in air, businesses can enhance their efficiency and compliance with environmental regulations. Customizing filters to these specifications not only optimizes operational performance but also contributes to sustainability efforts by reducing waste and conserving resources.

2025 Filter System Effectiveness by Type

Key Components of an Effective Filtering System: Materials and Technology

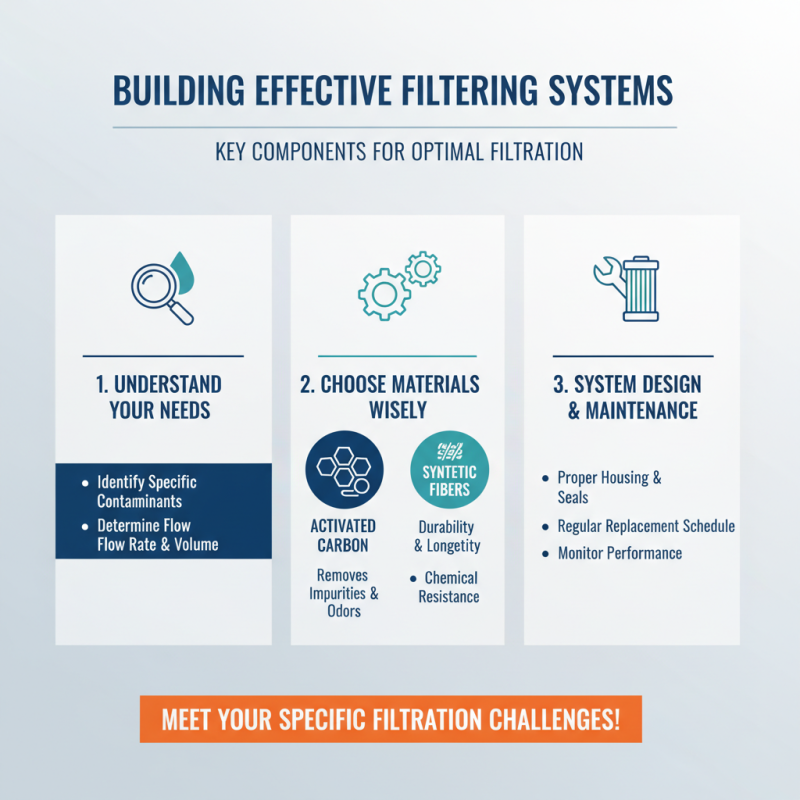

When building an effective filtering system, understanding the key components is crucial to meet your specific needs. The right materials play a significant role in ensuring durability and efficiency. Common filtering materials include activated carbon, which is excellent for removing impurities and odors, and various synthetic fibers that can provide fine filtration. Assessing the specific contaminants you wish to filter will guide your selection process, ensuring that you choose materials that can withstand the conditions they will be used in.

Technology also plays a vital role in the effectiveness of a filtering system. Innovations such as membrane filtration and advanced UV purification have significantly enhanced the capability of modern systems to eliminate harmful substances. Integrating smart technologies, like automated sensors that monitor filter performance, can optimize maintenance schedules and prolong the life of the system.

Tips: Always keep in mind the importance of regular maintenance checks for your filtering system. This includes replacing filters as recommended and inspecting for any wear and tear in the materials. Additionally, consider the environment in which your system operates, as factors such as humidity and temperature can impact its efficiency.

Understanding Flow Rate and Efficiency Metrics in Filter Systems

When building an effective filter system, understanding flow rate and efficiency metrics is crucial to cater to your specific needs. Flow rate represents the volume of fluid that passes through the filter system within a designated time. Higher flow rates may be necessary in applications where quick filtration is required, such as in aquariums or swimming pools. Conversely, slower flow rates may be more suitable for systems that prioritize thorough filtration over speed. To determine the ideal flow rate for your needs, consider both the volume of liquid to be filtered and the desired time frame for filtration.

Efficiency metrics, often expressed as a percentage, indicate how effective a filter is at removing contaminants from the fluid. Filters can be rated based on their ability to capture particles of specific sizes, so it's essential to choose a filter that aligns with your contaminants. For example, a filter with a 99% efficiency rate at 5 microns will effectively remove particles that size or larger.

Tips:

- Assess your environment: Different applications have different requirements. Perform an analysis to identify the primary contaminants in your water or air supply, which will guide your filter selection.

- Monitor your system: Regularly check the flow rate and efficiency to ensure your filter is functioning optimally. Regular maintenance can extend the life of your filter and maintain quality.

- Experiment with multiple designs: If possible, try various designs or models of filters to find the best combination of flow rate and efficiency for your specific situation.

Industry Standards and Regulations to Consider for Filter Systems

When building an effective filter system, it's crucial to understand and adhere to industry standards and regulations that govern the design and operation of such systems. Different industries have specific guidelines that ensure safety, efficiency, and environmental compliance. For instance, the water treatment sector must follow standards set by organizations like the Environmental Protection Agency (EPA) to ensure that drinking water is safe and free of harmful contaminants. Compliance with these regulations not only protects public health but also helps organizations avoid costly fines and legal repercussions.

Moreover, various industries require filters to meet stringent performance criteria, often defined by national and international standards such as ISO or ASTM. These standards outline testing methods and minimum performance levels, ensuring that filter systems perform effectively under specified conditions. For example, in the manufacturing sector, filters might need to demonstrate the ability to remove particulates to a precise size to prevent machinery damage and maintain operational efficiency. Therefore, understanding these regulations and standards is fundamental for anyone looking to develop a filter system tailored to their specific needs while ensuring compliance and effectiveness.

2025 How to Build an Effective Filter System for Your Needs - Industry Standards and Regulations to Consider for Filter Systems

| Filter Type | Application | Standards | Maintenance Frequency | Expected Lifespan (Years) |

|---|---|---|---|---|

| HEPA Filter | Air Purification | EN 1822 | 6-12 months | 3-5 |

| Activated Carbon Filter | Odor Removal | ASTM D3467 | 3-6 months | 1-2 |

| Bag Filter | Air Handling Units | ASME PTC 28 | 6-12 months | 2-4 |

| Inline Filter | Water Filtration | NSF/ANSI 42 | 6-12 months | 3-5 |

| Cartridge Filter | Pool & Spa | ASTM F1140 | 3-6 months | 2-3 |

Best Practices for Maintenance and Optimization of Your Filter System

When establishing a filter system, maintaining and optimizing its performance is critical for ensuring efficiency and longevity. Regular maintenance not only helps in identifying potential issues before they escalate but also keeps energy costs in check by ensuring that the system runs smoothly. One effective strategy is to set a maintenance schedule that includes regular checks on the filter condition, cleaning, and eventual replacement as needed. Keeping a log of maintenance activities can help track the system's performance over time.

Tips for Maintenance: Be proactive by examining your filters monthly and replacing them at intervals dictated by their condition. Additionally, ensure your filter system is free of obstructions to improve airflow and efficiency. It’s also beneficial to familiarize yourself with the specific needs of your filter type, as various systems may have unique maintenance requirements.

Optimization involves making informed adjustments based on your specific usage and performance metrics. For instance, if you notice a decrease in airflow or increases in energy consumption, it may be time to evaluate both the filter quality and the overall configuration of your system. Regularly analyzing these metrics can highlight areas for improvement, allowing for timely upgrades or adjustments that enhance performance.

Tips for Optimization: Keep detailed records of your system’s performance before and after maintenance to identify trends. Don't hesitate to consult with professionals for insights on advanced optimization tactics specific to your setup. By staying vigilant and adaptable, you can ensure that your filter system consistently meets your needs while operating at peak efficiency.

Related Posts

-

2025 How to Choose the Best Well Water Filtration System for Your Home

-

10 Essential Tips for Effective Well Water Maintenance You Need to Know

-

Top Benefits of Drinking Water Filtration Systems for Health and Taste

-

2025 Top Carbon Water Filters for Clean Drinking Water Solutions

-

How to Get Your Water Tested for Safety and Quality at Home

-

Understanding the Importance of a Well Water Filter System for Your Family's Health